Jimmy Lewis is a legend; he’s humble but proud of his art and legacy. I’ve personally had the honor of knowing Jimmy Lewis since 1981, when he made me a 9’1” big wave windsurfing gun for Hoo’Kipa. This was when Jimmy was the shaper in residence for Sailboards Maui, the first windsurfing shop on Maui. (Pictured Jimmy on his favorite SUP Surfboard the Black and Blue.)

Jimmy was already established as a great surfboard shaper and there was a waiting list for his custom windsurfing boards. I was lucky enough to have Jimmy shape and build countless world-class level slalom and wave boards for the Windsurfing World Cup., For over 40 years Jimmy has shaped me great custom boards for Windsurfing, Stand Up paddling, and, for the last 7 years, custom foil boards for both wave foiling and wingfoiling. Jimmy is a master craftsman, he’s an innovative perfectionist, and always true to his art and dead set against gimmicks and fads. When we first opened 101 Surf Sports, 12 years ago, we already knew where we wanted to go to get the best boards. Here’s a little bit about Jimmy and why we are loyal to his brand.

World Records

Whether it’s surfing the world’s biggest wave at Nazare, or competing in windsurfing and kiteboarding events globally Jimmy Lewis boards have been ridden to earn world records and world championships. When it comes to performance on the water, no one can match Jimmy Lewis’ track record for accomplishment. (Pictured below Pascal Maka World Speed Sailing Record holder on his Jimmy Lewis Speed Needle)

Location location location

Jimmy had been building and designing boards for over 50 years. During that time, Jimmy had one of the biggest advantages any shaper could have – the best testing and feedback loop in the business. The advantage of being Maui based meant that the world's best surfers, windsurfers, kiteboarders, paddlers, and foilers were riding Jimmy's boards and giving real-time feedback as to the design's performance. In addition, Jimmy wasn't just shaping–he and his son Marlon were watermen themselves out riding boards almost every day, as they looked for every angle to make the boards better.

Superior Technology and Constant refinement

Another big advantage of a Jimmy Lewis board is how the boards are made and who makes them. In 1985 Jimmy met James Chen, a talented board maker originally from Taiwan, who relocated to Vietnam and was producing the best boards under the Kinetic label. James refined the world’s best construction methodology using a complex material layup, the perfect resin-to-material ratio (which vacuumed off the excess resin) to produce the lightest and strongest boards in the world. All of Jimmy’s production boards are made in the Kinetic factory in Vietnam. Kinetic is a family-run business now run by James’s sons – Frank and Eric Chen at the helm. Their attention to detail and constant collaboration with Jimmy has resulted in one of the industry’s tightest partnerships. To say Kintetic and the Chens, are part of Jimmy’s secret sauce is an understatement.

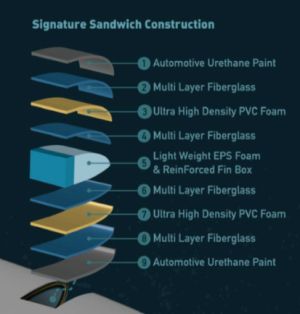

Without getting too technical, Kinetic’s methodology is a PVC sandwich with a vacuum bagging curing process. Kinetic creates an I-Beam by separating the layers of fiberglass, or carbon, with a layer of closed-cell PVC foam and then vacuuming off all the excess resin. Using the same principle that skyscraper designers use, the I-Beam creates a thicker and stronger exoskeleton for his boards. Science will tell you the farther you separate the layers the stronger the structure. This then allows him to use lower-density cores to save on weight. Most manufacturers are using heavier layups to create structural integrity whereas a Jimmy Lewis board is getting all the structure from its construction technique and curing process. Given that the shell is 4 to 5 times thicker than any other board manufacturer, you get an incredibly light and highly durable board.

Due to the expense and technical difficulty associated with this construction, only one or two manufacturers even attempt it. The problem is the other manufacturers are nearly twice as expensive as a Jimmy Lewis board. Jimmy's company is small with limited layers of distribution and minimal marketing keeping overhead low and allowing him to charge less for his boards. While Jimmy's boards are not cheap they are far and away the best value on the market today.

Don't believe us? Come into the shop and lift one and you'll say what everyone says. "OMG, I can't believe how light it is!!!" Then ride one and you'll say "Holy Sh*t this thing rips". Then own one and watch it become a family heirloom as it literally is made to last a lifetime.

Over the years we have become evangelists for Jimmy's boards and over a decade plus of selling boards has made us the world's biggest Jimmy Lewis dealer. A distinction we could not be prouder of. Why? Because we know when you buy a Jimmy you are buying the best board. Period.

Get to the know the whole Jimmy Lewis story with this indept interview from April 2023